Automation, high storage density and uninterrupted material flows are defining characteristics of modern logistics facilities. Fully automated high-bay warehouses, shuttle systems and large distribution centres place exceptional demands on fire protection systems – not only in terms of compliance, but also reliability, early detection and operational continuity.

Pyronova Group has been supporting these requirements for more than three decades. Through its subsidiaries across Europe, Pyronova delivers full-service fixed fire protection solutions, covering design, installation, and maintenance. Following the establishment of a strategic partnership with the Belgium-based Altebra Group, we are preparing to rebrand and operate together under the newly formed ALTENOVA Group, enabling pan-European fire protection solutions supported by strong local expertise.

Logistics and high-bay warehouses as a key focus area

Alongside large-scale industrial projects such as battery manufacturing plants, data centres and wood-processing facilities, logistics centres and automated warehouses represent a core segment of our activities. These environments combine high fire loads, compact storage, complex material handling systems and limited human presence – all factors that require carefully engineered, integrated fire protection concepts.

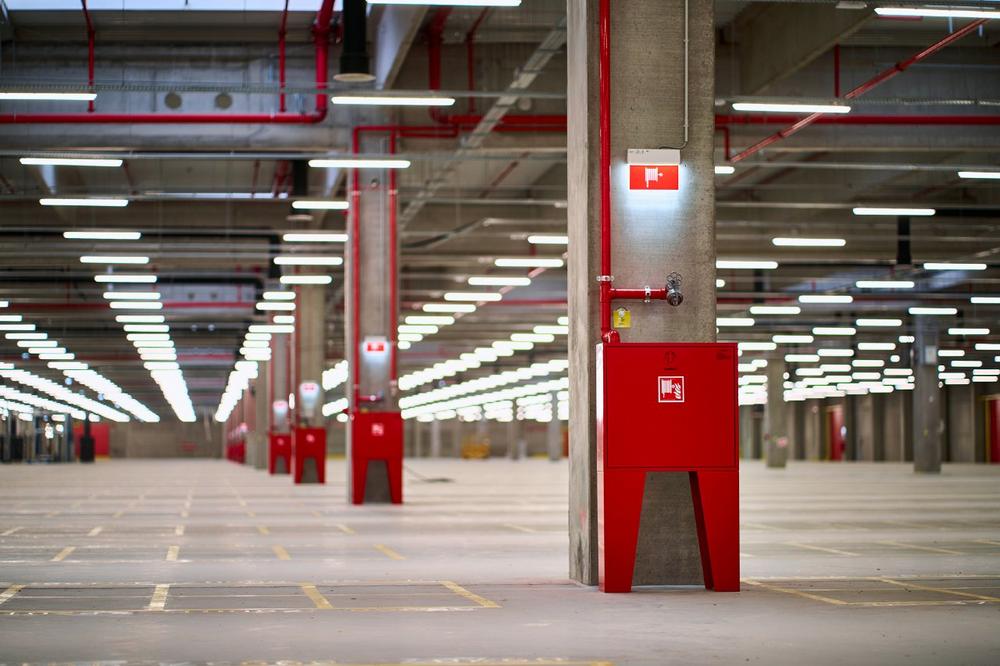

We deliver complex solutions for logistics facilities, including sprinkler protection for racks and roofs, fire detection and aspirating smoke detection, heat and smoke extraction control, hydrant systems, gas and foam extinguishing systems, as well as protection for shuttle technologies, conveyors, mezzanines and bag storage systems.

Sprinkler protection for racks and roofs in automated warehouses

In fully automated high-bay warehouses, sprinkler systems form the backbone of fire protection. Pyronova designs sprinkler solutions that address both in-rack fire scenarios and roof-level fire spread, even in facilities with extreme storage heights and dense racking layouts.

In one automated high-bay warehouse project in Central Europe, a protected volume of approximately 160,000 m³ required nearly 19,000 in-rack sprinkler heads, complemented by additional roof-level protection. In another logistics centre exceeding 40 metres in height, more than 140,000 sprinkler heads were installed to protect racks and roof structures across a total area of over 140,000 m².

Such systems are designed in accordance with internationally recognised standards such as VdS and FM Global, and tailored to the specific storage configuration, goods classification and automation level of each facility. Combined rack and roof protection ensures rapid fire control at the point of origin while limiting vertical and horizontal fire spread.

Aspirating smoke detection for early warning in high-bay logistics

Early fire detection is particularly critical in automated warehouses, where fires can develop unnoticed and spread rapidly before personnel become aware of the incident. In these environments, aspirating smoke detection systems (ASD) offer significant advantages over conventional point detectors.

Aspirating systems continuously sample air through a network of small pipes installed directly within racks, along conveyor routes or in critical zones. This enables very early detection of incipient smoke, even in warehouses with storage heights of 30 metres or more, strong airflows and thermal stratification.

In large distribution centres and automated silo warehouses protected by Pyronova, several hundred aspirating detection points have been deployed to provide early warning across areas exceeding 80,000 m². In one self-supporting rack warehouse storing tens of thousands of pallets, aspirating smoke detection is combined with ESFR sprinklers and gas extinguishing systems to protect both goods and critical technical rooms.

Early detection not only reduces potential fire damage, but also helps minimise downtime, protect high-value goods and support safe, targeted intervention by emergency services.

Integrated fire protection for reliable logistics operations

By combining sprinkler protection, early fire detection and intelligent system monitoring, Pyronova supports logistics operators in maintaining safe, efficient and resilient operations. From automated shuttle warehouses and high-bay distribution centres to retrofits and upgrades of existing buildings, Pyronova’s solutions are designed to meet the growing demands of modern intralogistics.

PYRONOVA IS Slovakia s.r.o.

Landererova 8

SK811 09 Bratislava

Telefon: +421 907 357733

http://www.pyronova.com/

Marketing Manager

Telefon: +421 (907) 357-733

E-Mail: zuzana.benkova@pyronova.com

![]()